why process mapping matters strategically

mid-sized firms that implement process mapping can reduce operational costs by up to 30% and boost efficiency by 40%.

for you, this clarity equals a strategic lens to focus investments and scale smarter.

but here’s the problem: most companies approach process mapping as a documentation exercise—creating diagrams that sit in SharePoint folders gathering digital dust.

the difference between documentation and strategic mapping

documentation approach (what most companies do)

characteristics:

- creates comprehensive process diagrams

- focuses on capturing current state accurately

- treats mapping as compliance or audit requirement

- produces artifacts that rarely get updated or used

- doesn’t drive actual operational improvement

the result: neat diagrams, no impact

strategic approach (what actually creates value)

characteristics:

- maps processes to identify improvement opportunities

- focuses on understanding bottlenecks and inefficiencies

- treats mapping as strategic investment in operational clarity

- produces insights that drive automation and optimization decisions

- becomes living tool for continuous improvement

the result: operational transformation

step-by-step process mapping for strategic impact

when you embrace process mapping as a strategic initiative—not just a tactical fix—it becomes a catalyst for clarity, innovation, and scalable efficiency.

1. define your business objectives first

before drawing a single line or box, identify the “why.”

critical questions:

- are you trying to reduce operational friction?

- increase output consistency and quality?

- improve customer experience at specific touchpoints?

- identify automation opportunities?

- prepare for scaling or system implementation?

align with measurable KPIs:

- cycle time (how long from start to finish?)

- error rates (how often do things go wrong?)

- cost per transaction or output

- customer satisfaction (NPS, CSAT scores)

- employee satisfaction (process pain points)

clear business intent ensures your process map becomes a tool for strategy—not just documentation.

2. map the as-is process in context

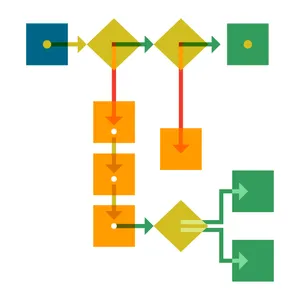

use industry-standard formats like BPMN (Business Process Model and Notation), swimlane diagrams, or value stream mapping to chart current workflows.

what to include:

all roles involved:

- human roles (by function or title)

- digital roles (systems, automation, tools)

- external parties (customers, suppliers, partners)

systems and tools:

- which software or platforms are used at each step?

- where does data get entered or retrieved?

- what integrations exist (or don’t exist)?

decision points:

- where do people make judgment calls?

- what criteria guide these decisions?

- who has authority to decide?

data handoffs:

- where does information move between people or systems?

- what format does it take?

- how could information get lost or corrupted in transfer?

external dependencies:

- where do you rely on third parties?

- what compliance requirements or approval gates exist?

- what external factors can delay or disrupt the process?

common mapping formats and when to use them

| format | best for | complexity |

|---|---|---|

| basic flowchart | simple, linear processes | low |

| swimlane diagram | processes crossing departments | medium |

| BPMN | complex processes needing detailed documentation | high |

| value stream mapping | identifying waste and non-value-adding steps | medium |

| user journey maps | customer-facing processes | medium |

3. surface friction and bottlenecks with data

layer in performance data: turnaround time, error rates, volume, cost per action.

look for:

manual entry or repetitive tasks:

- same data entered multiple times in different systems

- copy-paste operations that are error-prone

- routine data processing that follows clear rules

excessive approval layers:

- processes requiring 3+ approvals for routine decisions

- bottlenecks where one person’s availability delays everything

- approval steps that rarely reject but always delay

inconsistent outcomes:

- different people producing different quality results

- variability in cycle time depending on who handles it

- error rates varying significantly by operator

delays in handoffs or unclear ownership:

- work sitting in queues waiting for next person

- confusion about who’s responsible for next step

- information requests between departments creating delays

these are your hotspots—prime candidates for automation, delegation, or elimination.

mapping the invisible work

what often gets missed:

- rework loops when things are done wrong first time

- informal workarounds people use because official process doesn’t work

- waiting time between steps

- communication overhead coordinating handoffs

- context-switching costs when people juggle multiple processes

how to surface it:

- interview people who actually do the work (not just managers)

- observe processes in action, don’t just review SOPs

- ask “what slows you down?” and “what’s frustrating?”

- track actual cycle times, not theoretical ones

4. design the to-be future state with automation in mind

now shift from diagnostic to design. map the ideal “to-be” process using insights from your pain points.

ask:

can this step be digitized or automated?

- is it rule-based and repeatable?

- does it follow clear decision logic?

- is the data available electronically?

can we reduce human input without losing oversight?

- can we automate the routine and escalate the exceptions?

- where do humans add real judgment vs. just process work?

- what needs human creativity vs. what needs consistency?

how can low-code platforms plug into this flow?

- can we build simple forms to replace email requests?

- can we create automated workflows between systems?

- can we trigger notifications based on status changes?

prioritize areas where small automations yield big impact:

- invoice approvals (clear rules, high volume, low complexity)

- onboarding workflows (repetitive steps, consistency matters)

- CRM updates (data already captured elsewhere)

- status notifications (automated based on system events)

- report generation (data already exists, just needs formatting)

automate first: high-volume, rule-based, low-complexity tasks with clear success criteria

automate eventually: medium-volume tasks with some judgment required

keep human: low-volume, high-judgment, complex tasks requiring creativity

design principles for the future state

simplify before automating:

- eliminate unnecessary steps entirely

- combine related steps

- reduce approval layers

- remove redundant data entry

design for clarity:

- clear ownership at every step

- explicit handoff points with success criteria

- visible status throughout the process

- exception handling procedures defined

build in quality:

- validation at point of data entry

- automated checks before handoffs

- clear quality criteria at each step

- feedback loops for continuous improvement

5. validate with stakeholders across departments

engage the teams who live the process daily.

why validation matters:

- uncover missed details and informal workarounds

- identify constraints you didn’t know about

- get buy-in from people who’ll need to adopt changes

- surface concerns before they become resistance

how to validate effectively:

cross-functional workshops:

- bring together representatives from each involved department

- walk through the mapped process step by step

- ask “is this how it really works?” at each step

- capture feedback on sticky notes or digital whiteboard

individual interviews:

- talk to people who do the work daily

- ask about pain points and frustrations

- learn about unofficial workarounds and why they exist

- understand what would make their work easier

pilot testing:

- try the proposed future state with a small team

- run a few real transactions through new process

- measure actual results vs. theoretical benefits

- adjust based on real-world learning

getting stakeholder buy-in

communicate the why:

- explain business objectives driving the change

- show how current process creates problems for everyone

- demonstrate how improvements benefit their work directly

involve, don’t dictate:

- ask for their input on solutions

- acknowledge their expertise in the process

- incorporate their suggestions genuinely

- give credit for improvements they suggest

address concerns directly:

- listen to worries about job security or change

- clarify what’s changing and what isn’t

- provide training and support for new approaches

- commit to iterate based on their feedback

6. pilot, monitor, and refine using real-time metrics

launch with a focused scope. use your low-code platform to automate 1–2 critical workflows.

pilot selection criteria:

- high pain point (people will notice improvement)

- manageable scope (achievable in 4-8 weeks)

- measurable impact (clear before/after metrics)

- enthusiastic stakeholders (want it to succeed)

track performance metrics like:

cycle time reduction:

- before: average time from start to finish

- after: new average cycle time

- target: specific reduction goal (e.g., 30% faster)

accuracy improvements:

- before: error rate or rework percentage

- after: new error rate with process improvements

- target: specific quality goal (e.g., <2% errors)

SLA adherence:

- before: percentage meeting service level commitments

- after: improved SLA performance

- target: specific reliability goal (e.g., 95% on-time)

employee and customer satisfaction:

- before: baseline satisfaction scores

- after: satisfaction with improved process

- target: specific improvement (e.g., +20 NPS points)

cost per transaction:

- before: fully-loaded cost including labor, systems, overhead

- after: reduced cost through automation and efficiency

- target: specific savings goal (e.g., 25% cost reduction)

pilot success framework

- week 1-2: process mapping and future state design

- week 3-4: automation build and testing

- week 5-6: pilot launch and user training

- week 7-8: measure results and refine

- week 9+: scale successful changes, iterate on learnings

iterate based on what the data tells you:

don’t trust your assumptions—trust your metrics. if cycle time isn’t improving, dig into why. if users are frustrated, understand what’s not working.

consider layering in process mining tools:

process mining software analyzes actual system logs to show how processes really run (vs. how you think they run). this reveals:

- actual paths taken through the process

- deviations from standard procedure

- real bottlenecks based on data, not assumptions

- opportunities you might have missed

fractional & low-code wins others have seen

financial institution: loan approval transformation

challenge: loan approval process taking seven days, losing competitive deals

approach:

- mapped current approval workflow with 12 handoffs and 4 approval layers

- identified that 80% of delays were waiting for approvals, not actual review time

- designed automated credit check and risk scoring for standard loans

- kept human review only for complex or borderline cases

solution: low-code automation platform with integrated credit bureau APIs

results:

- cycle time reduced from seven to three days

- 85% of loans now approved automatically

- loan officers focus only on complex cases requiring judgment

- customer satisfaction improved 40%

humanitarian agency: crisis response acceleration

challenge: slow response to humanitarian crises due to manual coordination processes

approach:

- mapped emergency response workflows across 8 departments

- identified bottlenecks in resource allocation and authorization

- designed pre-approved response protocols for common scenarios

- automated notifications and status tracking

solution: code-free automation platform with mobile access

results:

- improved process transparency across distributed teams

- reduced response initiation time by 60%

- better coordination between field teams and headquarters

- documented processes for faster onboarding of crisis responders

the strategic edge: beyond operational efficiency

by combining sharp process mapping with fractional, low-code automation, you gain not just operational clarity—but a strategic edge.

you can pilot with purpose

instead of big-bang implementations:

- test improvements in controlled scope

- prove value before scaling investment

- learn what works in your specific context

- reduce risk of expensive failures

you can scale with confidence

because you understand:

- exactly which processes create value and which create waste

- where automation makes sense and where human judgment is essential

- how processes connect and affect each other

- what metrics indicate health vs. problems

you can continuously refine

with living documentation:

- process maps updated as improvements roll out

- performance data showing what’s working

- feedback loops from people doing the work

- culture of continuous optimization built over time

common pitfalls (and how to avoid them)

pitfall 1: mapping for mapping’s sake

the problem: creating comprehensive process documentation as compliance requirement without clear improvement objectives

why it fails: diagrams sit unused, don’t drive change, waste time and resources

do this instead: map only processes where you intend to drive improvement—let objectives guide mapping scope

pitfall 2: analysis paralysis

the problem: spending months mapping every subprocess in perfect detail before taking any action

why it fails: momentum dies, business context changes, people lose interest, delays value

do this instead: map at appropriate level of detail for your purpose—start improving while continuing to learn

pitfall 3: ignoring the people

the problem: mapping processes based on SOPs or management assumptions without talking to people who do the work

why it fails: you miss reality—workarounds, pain points, bottlenecks that aren’t documented

do this instead: interview and observe the people who live the process daily—they know where it breaks

pitfall 4: perfect future state syndrome

the problem: designing elaborate ideal processes requiring massive investment and organizational change

why it fails: too expensive, too disruptive, too complex to implement—nothing happens

do this instead: identify incremental improvements that move toward ideal state—progress over perfection

our suggestion: building process mapping into strategic practice

view process mapping as strategic investment

not diagramming chores, but:

- competitive intelligence about your own operations

- foundation for automation and digital transformation

- clarity that focuses resources where they matter

- capability that enables scalable growth

lean into fractional and low-code solutions

the winning combination:

- fractional process experts who’ve seen what works across industries

- low-code platforms that enable rapid pilots without IT backlogs

- small focused improvements that prove value quickly

- rapid wins that build momentum for bigger changes

why this works:

- lower cost than hiring full-time process team or custom development

- faster results than traditional BPM or transformation programs

- flexible engagement that scales with your needs

- knowledge transfer to build internal capability

embed process mining and iterative reviews

build culture of continuous optimization:

- regular process reviews (quarterly or semi-annually)

- process mining tools showing how things really work

- metrics dashboards making performance visible

- teams empowered to suggest and implement improvements

the sustainable approach:

- process mapping becomes ongoing capability, not one-time project

- improvements compound over time

- organization builds operational excellence muscle

- continuous adaptation keeps you competitive as markets evolve

next steps: your process mapping roadmap

month 1: strategic selection

identify high-impact process to map:

- causes most pain or delays

- handles highest volume or cost

- affects customer experience directly

- blocks scaling or growth

define clear objectives:

- what business outcome are you targeting?

- what metrics will show success?

- who are stakeholders that must be involved?

assemble mapping team:

- process participants from each involved area

- subject matter experts who know the work

- stakeholders who care about outcomes

- facilitation expertise (fractional resource works well)

month 2: mapping and design

map current state:

- interview participants and observe real work

- document actual process (not idealized SOP)

- identify bottlenecks, delays, and pain points

- gather performance data

design future state:

- eliminate unnecessary steps

- identify automation opportunities

- reduce handoffs and approvals where possible

- validate with stakeholders

month 3-4: pilot implementation

build and test improvements:

- implement 1-2 key changes or automations

- train users and provide support

- measure performance against baseline

- gather feedback and refine

measure and document:

- track improvement metrics

- document lessons learned

- capture success stories

- prepare case for scaling

month 5+: scale and iterate

expand what works:

- apply learnings to additional processes

- scale successful automations

- build internal capability

- embed continuous improvement culture

the bottom line

process mapping creates strategic value when approached as discovery and improvement—not documentation compliance.

the formula for success:

- start with clear business objectives driving the mapping effort

- map thoughtfully to understand reality, not document theory

- design pragmatically for incremental improvement, not perfection

- validate collaboratively with people who do the work

- pilot rapidly using low-code tools and fractional expertise

- measure rigorously to prove value and guide scaling

- iterate continuously building operational excellence culture

the results:

- 30% operational cost reductions

- 40% efficiency improvements

- clearer processes that scale

- automation opportunities identified and captured

- culture of continuous improvement

mid-sized firms that master process mapping don’t just document what they do—they transform how they operate, creating competitive advantage through operational excellence.

the question isn’t whether to map your processes—it’s whether you’ll do it strategically or just for compliance.

one approach creates transformation. the other creates dusty diagrams.

ready to map your business processes strategically and identify automation opportunities? let’s chat about focused pilots that deliver measurable operational improvements.